Log Home Packages

Log construction has its roots in Scandinavia, the Baltic states and Russia, where straight and tall coniferous trees such as pine and spruce are readily available – as opposed to the more westerly regions of Europe, where deciduous trees, more suitable for timber framing, predominate. In contrast to vertical timber-frame structures, log homes use horizontal timbers, usually also exposed on the inside of the structure.

RMJC’s CNC facility is equipped to design and fabricate complex log home packages using only uniform round logs or dimensional squared timbers.

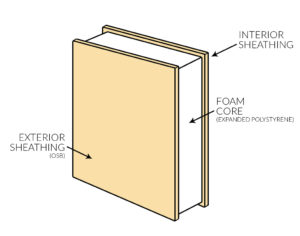

SIP Packages

(Structurally Insulated Panel)

As an alternative to stick-framing, SIPs consist of an insulating foam core sandwiched between two structural facings, typically OSB. SIPs reduce dependency on bracing, add rigidity to the existing timber frame, and provide superior insulation. Construction using SIPs is faster and less complex than traditional stick frame building.

CNC pre-fabrication of a SIPs shell package in a controlled environment dramatically reduces job-site expense and waste. In conjunction with architects, RMJC designs the SIP shell, then pre-cuts the panels to fit the existing timber frame. Our Hundegger K2i machine is equipped with the widest track available, and can accommodate panels 48” wide and up to 40’ long.

CLT Packages

(Cross Laminated Timber)

Developed in Europe in the 1990s, CLT is the latest in engineered wood products that are strong and rigid enough to replace steel and concrete in larger, taller buildings. CLT panels consist of layers of narrow planks, about 1” thick, laid perpendicular to the preceding one. The layers are glued and the entire sandwich is pressed and trimmed. Construction using CLT panels tends to be cheaper and more environmentally friendly than other materials.

Using CNC machinery, the panels can be cut to the precise dimensions in the architectural plans, including window, door, plumbing and ventilation openings. Channels for electrical wiring can also be cut into the panels.

Glulam Packages

(Glue Laminated Timber)

Glulam is a structural timber product comprising multiple layers of dimensioned timber bonded together with structural adhesive. Glulam members can be manufactured from a variety of smaller trees harvested from second- and third-growth forests, and provides the strength and versatility of large wood members without relying on old-growth solid-sawn timbers. Glulam allows for longer spans, heavier loads, and complex shapes. It is two-thirds the weight of steel and one-sixth the weight of concrete.

RMJC’s state-of-the-art CNC facility can pre-fabricate Glulam members measuring 18” x 48” x 60’ long for any residential commercial or industrial project.

Trusses & Component Packages

RMJC fabricates a wide range of timber components such as trusses, rafter tails, timber accents, awnings, entryways, brackets, braces, porches and stair systems. We accept architect-supplied CAD drawings for custom projects, or customers can request a detailed catalog of standard RMJC designs.

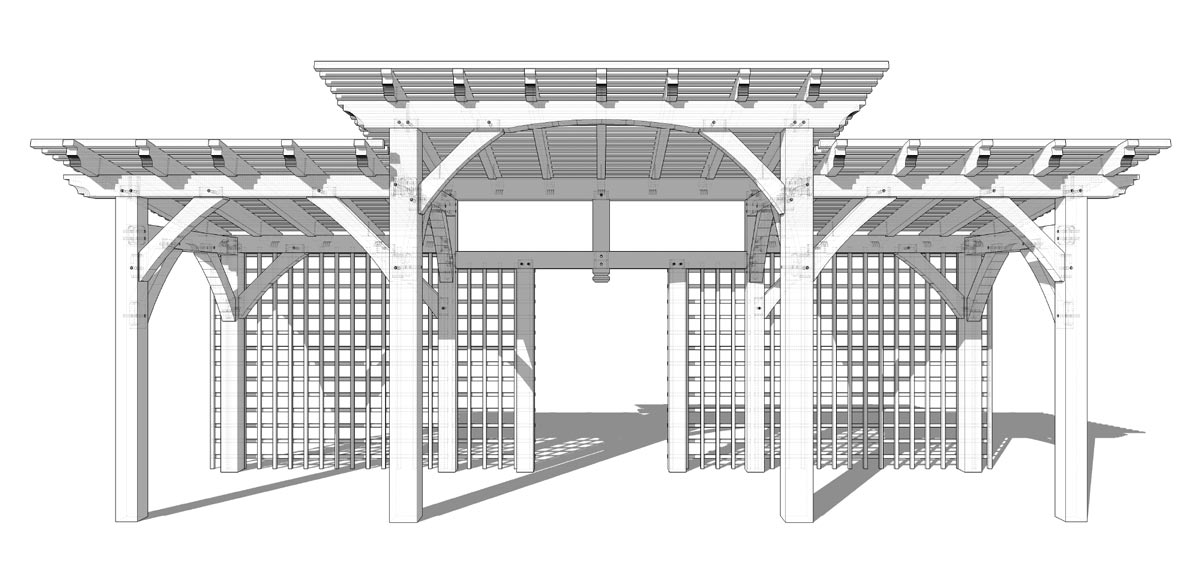

Outdoor & Modular Products

RMJC fabricates a wide variety of heavy timber outdoor structures such as pergolas, gazebos, carports, sheds, decks, porches, signage and bridges. In addition, we have an extensive design collection of heavy timber furniture such as tables, benches, beds and flowerbeds to choose from.

Pre-Built Wall / Floor / Stair Systems

Pre-assembly of timber components in a controlled environment provides greater precision, better cost control, and reduces job-site expense and waste.

RMJC manufactures a complete range of wall, roof, floor, truss or stair packages for any structure. All pre-built packages are precision cut and fully assembled in our facility, and are dispatched to the job site ready for installation.

- Wall systems with/without sheeting

- Stick-frame roof systems (2×8 up to 2×12 pre-cut)

- Trusses (>8x timbers, over 8′, max 12/12 pitch)

- Stick-frame stair systems